Lockout Tagout (LOTO) is more than just a safety procedure—it’s a life-saving standard in modern industry. Especially in workplaces where hazardous energy is present, such as during electrical or mechanical maintenance, LOTO ensures that equipment is properly shut off and not restarted until the work is safely completed. This article breaks down how LOTO systems work, the essential tools involved, and why they’re vital in both domestic and industrial environments.

Understanding the Purpose of LOTO

The primary goal of LOTO procedures is to control hazardous energy and prevent accidental start-up of equipment during maintenance or servicing. These procedures include the placement of lockout devices (locks) and tagout devices (tags) to clearly communicate that a machine or system is under maintenance and must not be operated. It’s a critical barrier that protects both workers and equipment from potential injury or damage.

Common LOTO Tools and Their Uses

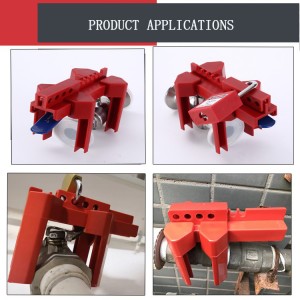

Different types of locks and tags are used depending on the nature of the equipment. Lockout Hasps allow multiple workers to attach their individual locks, ensuring no single person can restore power prematurely. Breaker Lockouts are designed specifically for circuit breakers to prevent accidental power flow. Valve Lockouts securely block valves to stop hazardous liquids or gases from being released. Lastly, Plug Buck (ETS) devices are used for electrical plugs, adding an extra layer of safety when equipment is disconnected.

The Role of Signage in LOTO

One of the simplest yet most powerful elements in a LOTO system is the warning tag. These cards often read, “Human maintenance/operation, do not start/close,” serving as a clear, visual cue. It tells everyone around that a person is actively working on the system—this visual alert helps avoid accidental startups and reinforces awareness in busy or high-risk environments.

Global Adoption and Best Practices

In Europe and the United States, LOTO systems are widely adopted and often mandatory under occupational safety regulations. Enterprises have developed specific maintenance and operating procedures, particularly in electrical and mechanical domains, that integrate LOTO as a core element. This not only improves compliance but also builds a culture of safety where everyone understands the value of protecting life over productivity.

Post time: Apr-07-2025